Introduction to Cattle Feed Plants

The establishment of efficient cattle feed plants is crucial for the livestock industry, as it ensures the consistent production of high-quality feed capable of meeting the nutritional demands of cattle. Such facilities are designed to process anywhere from 1 to 100 tons of feed per hour, adhering to stringent industry standards and requirements that guarantee optimal feed quality and safety.

Manufacturing cattle feed involves a series of complex processes, from the selection of raw materials to the mixing, grinding, and pelletizing stages. Each step requires precision and adherence to industry protocols to produce feed that supports the health and productivity of the cattle. Utilizing advanced equipment and technologies is essential in achieving these objectives efficiently and sustainably.

Companies like Richi Machinery offer comprehensive solutions for cattle feed production, including the provision of cutting-edge equipment and turnkey project services. Richi Machinery’s advanced equipment ensures minimal operational downtime, maximized productivity, and consistent feed quality. By integrating state-of-the-art machinery into the feed production line, manufacturers can enhance the efficiency of the entire process, from raw material handling to packaging.

The benefits of utilizing such advanced equipment in cattle feed plants are manifold. Not only do these technologies streamline operations and reduce labor costs, but they also enhance the precision and consistency of feed production. This, in turn, leads to improved cattle health and growth, ultimately benefiting livestock farmers through higher yields and better meat and milk production.

In summary, the development of efficient cattle feed plants is imperative for producing high-quality feed at scale. Adhering to industry standards and leveraging advanced equipment and turnkey services, such as those provided by Richi Machinery, ensures that feed production remains efficient, cost-effective, and sustainable, contributing to the overall prosperity of the livestock industry.

Case Study 1: Program Design Problems and Solutions

Program design is pivotal in setting up a cattle feed plant, as it determines the plant’s ability to efficiently produce high-quality feed. In one notable project, Richi Machinery faced significant challenges in feed formulation, production capacity planning, and process workflow design. These issues had the potential to hinder the plant’s operational efficiency and product quality, thereby affecting the client’s business outcomes.

The initial challenge was related to feed formulation. The client required a diverse range of feed products tailored to different stages of cattle growth. It was essential to achieve the right balance of nutrients to ensure optimal cattle health and productivity. To address this, Richi Machinery leveraged its extensive research and development capabilities to create scientifically-backed feed formulations. By integrating modern nutritional analytics and software tools, they were able to customize feed recipes precisely matching the nutritional needs of each growth phase.

Another critical challenge was planning the production capacity. The client projected fluctuating demands and needed a flexible yet efficient production system. Richi Machinery conducted a thorough analysis of the local market demand and the client’s business objectives. They then designed a scalable production capacity model that allowed for easy adjustments according to seasonal variations or market trends. This model not only optimized resource usage but also ensured consistent feed supply without overburdening the plant’s infrastructure.

The process workflow design posed its unique complexities, especially in organizing seamless operations. To streamline the workflow, Richi Machinery utilized advanced process mapping tools to identify bottlenecks and inefficiencies. They implemented an automated system that facilitated smooth transitions between different production stages, from grinding and mixing to pelleting and packaging. This resulted in enhanced operational efficiency, reduced downtime, and lower labor costs.

Through these tailored solutions, Richi Machinery successfully resolved the program design issues for the cattle feed plant, delivering a robust system that met the client’s specifications while also paving the way for future scalability and operational excellence.

Case Study 2: Overcoming Site Management Challenges

In one of our recent projects, Richi Machinery faced several formidable site management challenges when establishing a state-of-the-art cattle feed plant. The first hurdle was the intricate process of site selection. The client required a location that would not only support operational efficiency but also comply with environmental regulations. After a series of consultations and field assessments, our team pinpointed an optimal site that balanced accessibility to raw materials and distribution channels while meeting all regulatory standards.

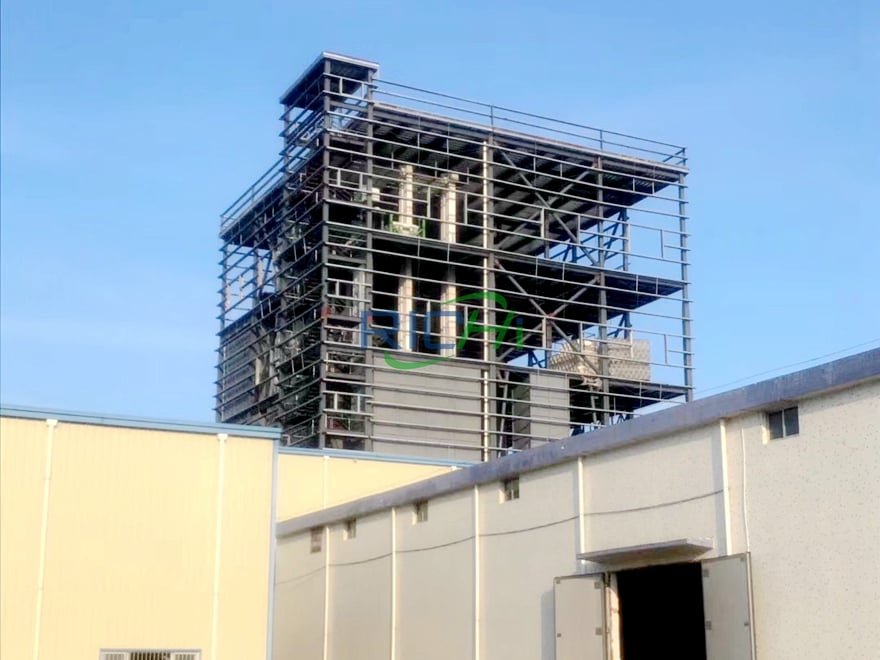

Space constraints presented another significant challenge. The designated plot posed limitations that initially appeared to hinder the extensive infrastructure needed for a fully operational cattle feed plant. Richi Machinery’s engineers employed innovative design strategies, optimizing vertical space and enhancing storage solutions to maximize the limited area without compromising on functionality. Through meticulous planning, we devised a layout that incorporated all necessary equipment and workflow processes within the given constraints.

Logistics also realized its share of complexities. The selected site had limited routes for ingress and egress, which could potentially disrupt the steady supply chain essential for continuous production. To address this, our logistics team conducted thorough route assessments and coordinated closely with local authorities. We implemented staggered delivery schedules and employed advanced tracking systems to monitor transporting goods efficiently, thereby mitigating any potential delays.

Regulatory compliance remains a critical aspect of cattle feed plant operations. Adhering to local and international standards, our compliance team navigated through a myriad of bureaucratic procedures. We liaised with environmental agencies to ensure that wastewater management, emissions control, and waste disposal were all meticulously aligned with statutory requirements. By undertaking comprehensive environmental impact assessments and obtaining all requisite permits, we paved the way for the plant’s smooth operational commencement.

Ultimately, each obstacle encountered during the site management phase was adeptly overcome through strategic planning, innovative design, and collaborative effort. Richi Machinery’s expertise and commitment ensured that the cattle feed plant was not only established successfully but also poised for long-term operational excellence, meeting both client and regulatory expectations.

Case Study 3: Equipment Selection and Configuration Issues

Main equipment: Cattle feed pellet machine

One of the most critical aspects of establishing an efficient cattle feed plant is the meticulous selection and configuration of equipment. The challenges in this domain are multifaceted, encompassing issues of equipment compatibility, performance efficiency, and cost considerations. Ensuring that each piece of machinery not only operates optimally on its own but also integrates seamlessly with the entire system is a primary concern.

Richi Machinery addresses these challenges through a robust and systematic approach to equipment selection and configuration. Their primary focus lies in identifying high-quality ring mold equipment known for its durability and superior performance. This particular equipment is instrumental in the production process, ensuring that the feed pellets are uniform and maintain nutritional integrity.

Compatibility is paramount in the configuration of a cattle feed plant. Richi Machinery ensures that each piece of selected equipment performs efficiently and aligns perfectly with the other machinery in the plant. This is achieved through rigorous compatibility testing and simulation exercises before the final installation. Such proactive measures help preempt potential operational hiccups and enhance the overall efficiency of the plant.

Efficiency in performance is another critical area. Richi Machinery’s expert team conducts thorough evaluations of equipment based on critical performance metrics such as energy consumption, output capacity, and ease of maintenance. By doing so, they select equipment that not only meets the immediate needs of production but also supports long-term operational sustainability.

Cost considerations are integral to the decision-making process. Richi Machinery balances the need for high-performing equipment with budget constraints, ensuring that customers receive optimal value for their investments. They provide detailed cost-benefit analyses and present multiple equipment options, enabling customers to make informed decisions that align with their financial plans.

Overall, Richi Machinery’s approach to equipment selection and configuration underscores the importance of a holistic and integrated strategy. By focusing on compatibility, efficiency, and cost-effectiveness, they ensure that every cattle feed plant operates at peak performance, delivering high-quality feed consistently and reliably.

The installation phase of a cattle feed plant is a critical juncture that often encounters various challenges. A particular case involved a project where technical complexity, stringent deadlines, and coordination with local contractors posed significant hurdles. Despite these challenges, Richi Machinery demonstrated exceptional competence in ensuring the smooth implementation of the cattle feed plant through meticulous planning, expert supervision, and adaptive problem-solving techniques.

One of the primary difficulties was the technical complexity of the machinery involved. Sophisticated equipment, integral to the productivity of the cattle feed plant, required precise installation and calibration. Richi Machinery tackled this by providing on-site technical experts capable of resolving intricate technical issues. These experts conducted comprehensive training sessions for the local workforce to ensure they understood the machinery’s operational intricacies, thereby preventing future operational disruptions

Additionally, the project was under a tight schedule, and timely completion was crucial. Richi Machinery devised a detailed project timeline that accounted for potential delays. Constant communication with the client and local contractors allowed for real-time adjustments, ensuring that the project remained on track. By anticipating bottlenecks and preparing contingency plans, they adhered to the deadlines effectively without compromising the quality of installation.

Coordination with local contractors presented another significant challenge. Varied working methods and communication styles initially hindered collaboration. Richi Machinery’s project managers bridged these gaps by fostering a cooperative environment. Regular meetings and clear directives facilitated a unified approach, encouraging seamless cooperation among all stakeholders involved. Moreover, by allocating a dedicated liaison officer to manage interactions between the team and local contractors, Richi Machinery streamlined the coordination process.

This case study underscores the importance of methodical planning, technical expertise, and effective communication in installing cattle feed plant equipment. Richi Machinery’s proficient handling of installation complexities exemplifies how proactive and responsive strategies can overcome seemingly insurmountable obstacles, ensuring successful project execution.

Maintaining Equipment: Common Problems and Preventive Strategies

Maintaining the equipment in a cattle feed plant is crucial to ensuring dependable and efficient production processes. One of the common issues encountered in these operations is wear and tear on machinery. Components such as grinders, mixers, and conveyor belts undergo constant stress, which can lead to frequent breakdowns if not properly managed. Regular inspection and timely replacement of parts are paramount to mitigating this problem. Operators should be diligent in identifying signs of wear such as unusual noises, vibrations, and decreased performance.

Another critical aspect is adhering to a strict routine maintenance schedule. This involves periodic cleaning, lubricating moving parts, and calibrating equipment to maintain precision and efficiency. Following the manufacturer’s guidelines for maintenance intervals helps avoid unscheduled downtimes. Furthermore, having a comprehensive maintenance log can assist in early detection of recurring issues, facilitating proactive measures rather than reactive fixes.

Troubleshooting mechanical issues is another facet of maintaining a cattle feed plant. Common problems such as hydraulic system failures, electrical malfunctions, and motor issues require immediate attention. The establishment of a well-trained maintenance team capable of diagnosing and resolving these issues swiftly is essential. Investing in training programs and continuous education for technical staff ensures that they are equipped to handle complex problems.

Richi Machinery’s preventive strategies and maintenance protocols exemplify best practices in this field. Their approach includes providing detailed maintenance manuals, routine check-up services, and prompt after-sales support. By following these guidelines, cattle feed plants can achieve long-term operational efficiency and reliability. In addition, their advanced diagnostic tools aid in pinpointing issues before they escalate, significantly reducing the chances of unexpected machinery failures. This holistic maintenance strategy not only extends the lifespan of equipment but also maximizes productivity, ensuring that the feed plant operates optimally at all times.

After-Sales Support: Addressing Client Concerns and Providing Ongoing Assistance

After-sales support plays a pivotal role in maintaining the efficient operation of a cattle feed plant. Post-installation, clients often encounter various issues requiring immediate attention, such as the need for technical assistance, timely parts replacement, and operational guidance. Recognizing these challenges, Richi Machinery has developed a robust after-sales support framework to ensure that clients can keep their operations running smoothly without any interruptions.

One of the core elements of Richi Machinery’s after-sales support is their responsive customer service. Clients can reach out via multiple channels, including phone, email, and online chat, for quick resolutions to their queries. The customer service team is well-trained to handle a wide range of issues from basic troubleshooting to more complex operational queries, ensuring that clients feel supported at every step.

Technical support is another critical aspect of after-sales service. Richi Machinery offers round-the-clock technical assistance to address any machinery malfunctions or operational hiccups a cattle feed plant might experience. Qualified technicians are on standby to provide remote guidance or dispatch on-site support when necessary. This proactive approach minimizes downtime and ensures the cattle feed production process remains uninterrupted.

Parts replacement is an inevitable aspect of managing a cattle feed plant. To address this, Richi Machinery maintains an extensive inventory of spare parts and components readily available for prompt dispatch. Their efficient logistics network ensures that replacements reach clients in the shortest time possible, thereby preventing prolonged periods of inactivity in the plant’s operations.

Furthermore, Richi Machinery emphasizes continuous improvement services. They frequently offer training sessions and workshops to keep their clients updated with the latest technological advancements and best practices in cattle feed production. This ongoing education not only optimizes the current performance of the cattle feed plant but also prepares it for future challenges and expansions.

In essence, Richi Machinery’s comprehensive after-sales support system addresses all potential client concerns, providing a well-rounded package of customer service, technical support, and continuous improvement. This thorough approach ensures that cattle feed plant operations remain efficient, reliable, and future-ready.

Conclusion: The Advantages of a Turnkey Approach with Richi Machinery

Opting for a turnkey project approach with Richi Machinery offers numerous advantages for establishing and operating a successful cattle feed plant. Throughout this comprehensive guide, we have discussed the pivotal elements required for an effective cattle feed plant, including meticulous program design, efficient site management, appropriate equipment selection, precise installation, proactive maintenance, and dedicated after-sales support. Richi Machinery’s expertise in these areas ensures that their clients receive tailored solutions that are both innovative and practical.

One of the primary advantages of choosing Richi Machinery for a turnkey project is the seamless integration of all necessary components from initial design to final operation. Their specialized team works closely with clients to develop detailed program designs that align with specific requirements and production targets. This meticulous planning phase lays a robust foundation for the subsequent stages of the project.

Site management is another crucial facet where Richi Machinery excels. Their comprehensive understanding of the logistics involved ensures that all aspects of site preparation and development are handled efficiently, minimizing potential delays and disruptions. By overseeing the entire site management process, Richi Machinery guarantees that the cattle feed plant is set up in an optimal environment conducive to high productivity.

The selection of appropriate equipment is paramount to the success of any cattle feed plant. Richi Machinery offers a broad range of advanced machinery, tailored to fit the unique needs of each project. Their commitment to quality and innovation ensures that clients receive state-of-the-art equipment that enhances operational efficiency and product quality.

Installation is executed with precision, ensuring that each piece of equipment is correctly set up and integrated into the process. Richi Machinery’s experienced technicians manage the installation process meticulously, ensuring smooth commissioning and start-up of the cattle feed plant. This attention to detail reduces the risk of operational issues and facilitates a faster transition to full-scale production.

Maintenance and after-sales support are critical for the ongoing success and longevity of a cattle feed plant. Richi Machinery provides comprehensive maintenance services and robust after-sales support, helping to resolve any issues promptly and minimize downtime. This continuous support ensures that the plant operates at optimal efficiency, safeguarding the client’s investment over the long term.

In summary, Richi Machinery’s turnkey project approach offers a holistic solution encompassing every aspect of cattle feed plant establishment and operation. Their dedication to quality, innovation, and client satisfaction ensures that each project not only meets but exceeds expectations, making them a trusted partner in the cattle feed industry. Related: https://www.richimanufacture.com/goat-feed-pellet-making-machine/