In the ever-evolving landscape of sustainable agriculture and waste management, innovative solutions are crucial for addressing the challenges posed by the growing global population and the need for environmentally friendly practices. One such solution that has gained significant traction is the organic fertilizer granulator machine, a specialized equipment designed to transform organic waste into nutrient-rich fertilizer granules, promoting sustainable farming practices and contributing to a circular economy.

The Importance of Organic Fertilizers

Organic fertilizers play a vital role in promoting sustainable agriculture by providing essential nutrients to plants, improving soil structure, and enhancing microbial activity. Unlike chemical fertilizers, organic fertilizers are derived from natural sources, such as animal manures, plant residues, and composted materials, making them an environmentally friendly and renewable resource. The benefits of organic fertilizers include:

- Improved Soil Health: Organic fertilizers enhance soil structure, water-holding capacity, and microbial activity, promoting long-term soil fertility and reducing the risk of erosion.

- Reduced Environmental Impact: Organic fertilizers do not contribute to water pollution, soil acidification, or greenhouse gas emissions, making them a more environmentally friendly choice.

- Increased Crop Resilience: Plants grown with organic fertilizers often exhibit increased resistance to pests, diseases, and environmental stresses, leading to improved crop yields and quality.

- Nutrient Cycling: Organic fertilizers contribute to the natural cycling of nutrients within the ecosystem, reducing the need for external inputs and promoting a more sustainable agricultural model.

The Role of Organic Fertilizer Granulator Machines

Organic fertilizer granulator machines play a crucial role in transforming organic waste into a valuable resource – nutrient-rich fertilizer granules. These specialized machines are designed to handle a wide range of organic materials, such as animal manures, crop residues, food waste, and composted materials, ensuring efficient and reliable granule production.The typical workflow of an organic fertilizer granulator machine includes the following key stages:

- Raw Material Handling and Preparation: The first step involves the collection, sorting, and preprocessing of organic materials. This may include drying, shredding, or size reduction to ensure optimal granule production.

- Grinding and Sizing: The preprocessed organic materials are fed into a grinding mill, where they are reduced to a consistent particle size, typically between 3-6 mm. This step is crucial for achieving uniform granule quality and efficient compression during the granulation process.

- Conditioning: The ground organic material is conditioned with steam or water to increase its temperature and moisture content. This conditioning process softens the material, facilitating the binding of particles during the granulation process.

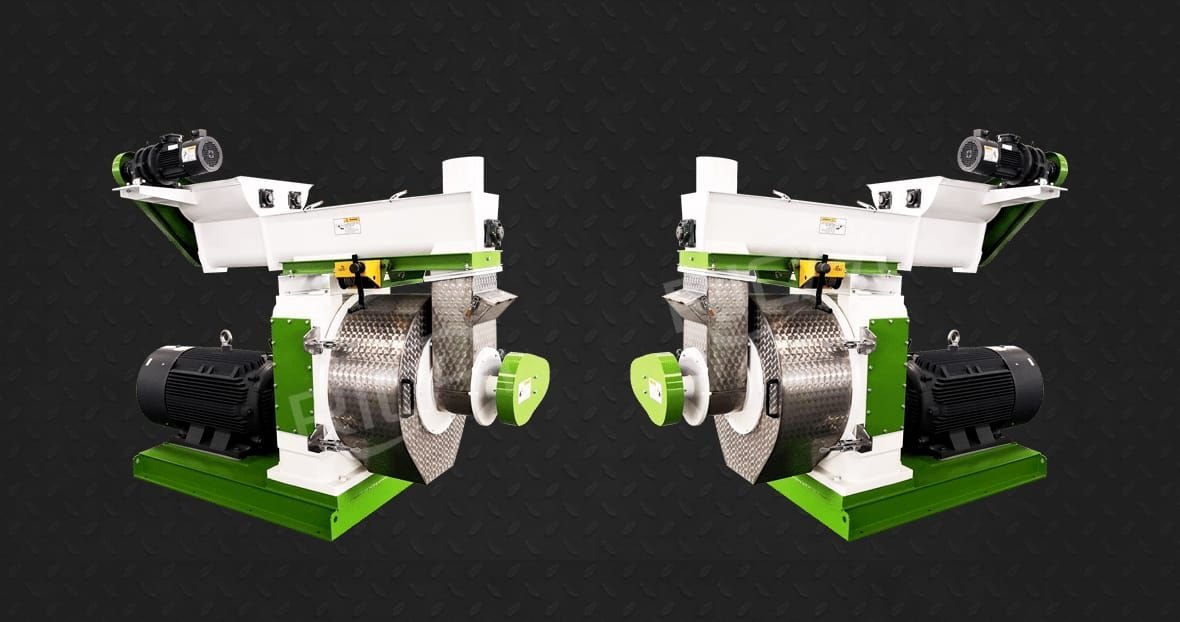

- Granulation: The conditioned organic material is fed into the granulator machine, where it is compressed and extruded through small die holes by rotating rollers or a ring die. The resulting granules are cut to the desired size by knives or a die, ensuring a consistent shape and size.

- Cooling and Drying: After granulation, the hot granules are rapidly cooled and dried to prevent further moisture absorption and maintain their structural integrity. This step is crucial for ensuring the durability and quality of the final product.

- Screening and Packaging: The cooled granules are screened to remove any fines or oversized particles, ensuring a consistent product. Finally, the granules are packaged in bags or bulk containers for storage and distribution.

Factors Influencing Granule Quality and Efficiency

The quality and efficiency of organic fertilizer granules produced by these machines are influenced by several critical factors, including:

- Raw Material Quality: The type and quality of the organic materials used as feedstock significantly impact the granule quality and production efficiency. Consistent and uniform raw materials are essential for optimal performance.

- Particle Size Distribution: Achieving a uniform particle size distribution through proper grinding is crucial for efficient granulation and granule durability.

- Conditioning Parameters: The temperature, moisture content, and conditioning time play a vital role in determining granule quality, durability, and energy consumption during the granulation process.

- Die Specifications: The size, shape, and compression ratio of the die holes in the granulator machine affect the physical characteristics and density of the granules, as well as the energy requirements for the granulation process.

- Cooling Rate: Rapid and efficient cooling is necessary to prevent granule degradation and maintain structural integrity, ensuring a consistent and high-quality product.

- Maintenance and Optimization: Regular maintenance and optimization of the organic fertilizer granulator machine, including die replacement, roller adjustment, and process parameter tuning, are essential for maintaining optimal performance and efficiency.

Related post:https://www.richipelletmachine.com/organic-fertilizer-production-line/

Advancements and Future Outlook

The organic fertilizer pelleting machine industry is continuously evolving, driven by the need for increased efficiency, automation, and sustainability. Advancements in areas such as process control, energy optimization, and alternative organic materials are shaping the future of organic fertilizer granule production.

One notable development is the integration of advanced technologies, such as the Internet of Things (IoT) and machine learning, into organic fertilizer granulator machines. These technologies enable real-time monitoring, predictive maintenance, and optimized process control, further enhancing the performance and efficiency of the machinery.

Additionally, the industry is exploring the use of alternative organic materials, such as agricultural residues, forestry by-products, and municipal solid waste, as potential feedstocks for organic fertilizer granule production. These alternative sources not only contribute to the sustainability of the industry but also provide opportunities for resource utilization and waste reduction.

As the global demand for sustainable agricultural practices and waste management solutions continues to rise, the role of organic fertilizer granulator machines will become increasingly crucial in meeting the needs of farmers, municipalities, and environmentally conscious consumers. With ongoing research and innovation, these machines will continue to evolve, ensuring the efficient transformation of organic waste into valuable fertilizer granules, contributing to a more sustainable and resilient agricultural ecosystem.

In conclusion, organic fertilizer granulator machines are at the forefront of the sustainable agriculture and waste management revolution, transforming organic waste into a valuable resource. As the world continues its journey towards a greener and more responsible future, these specialized machines will play a pivotal role in promoting circular economy principles, reducing environmental impact, and supporting sustainable farming practices, paving the way for a more prosperous and eco-friendly tomorrow.