In the ever-evolving landscape of sustainable agriculture and waste management, innovative solutions are crucial for addressing the challenges posed by the growing global population and the need for environmentally friendly practices. One such solution that has gained significant traction is the organic manure making machine, a specialized equipment designed to transform organic waste into nutrient-rich manure, promoting sustainable farming practices and contributing to a circular economy.

The Importance of Organic Manure

Organic manure plays a vital role in promoting sustainable agriculture by providing essential nutrients to plants, improving soil structure, and enhancing microbial activity. Unlike chemical fertilizers, organic manure is derived from natural sources, such as animal waste, plant residues, and composted materials, making it an environmentally friendly and renewable resource. The benefits of organic manure include:

- Improved Soil Health: Organic manure enhances soil structure, water-holding capacity, and microbial activity, promoting long-term soil fertility and reducing the risk of erosion.

- Reduced Environmental Impact: Organic manure does not contribute to water pollution, soil acidification, or greenhouse gas emissions, making it a more environmentally friendly choice.

- Increased Crop Resilience: Plants grown with organic manure often exhibit increased resistance to pests, diseases, and environmental stresses, leading to improved crop yields and quality.

- Nutrient Cycling: Organic manure contributes to the natural cycling of nutrients within the ecosystem, reducing the need for external inputs and promoting a more sustainable agricultural model.

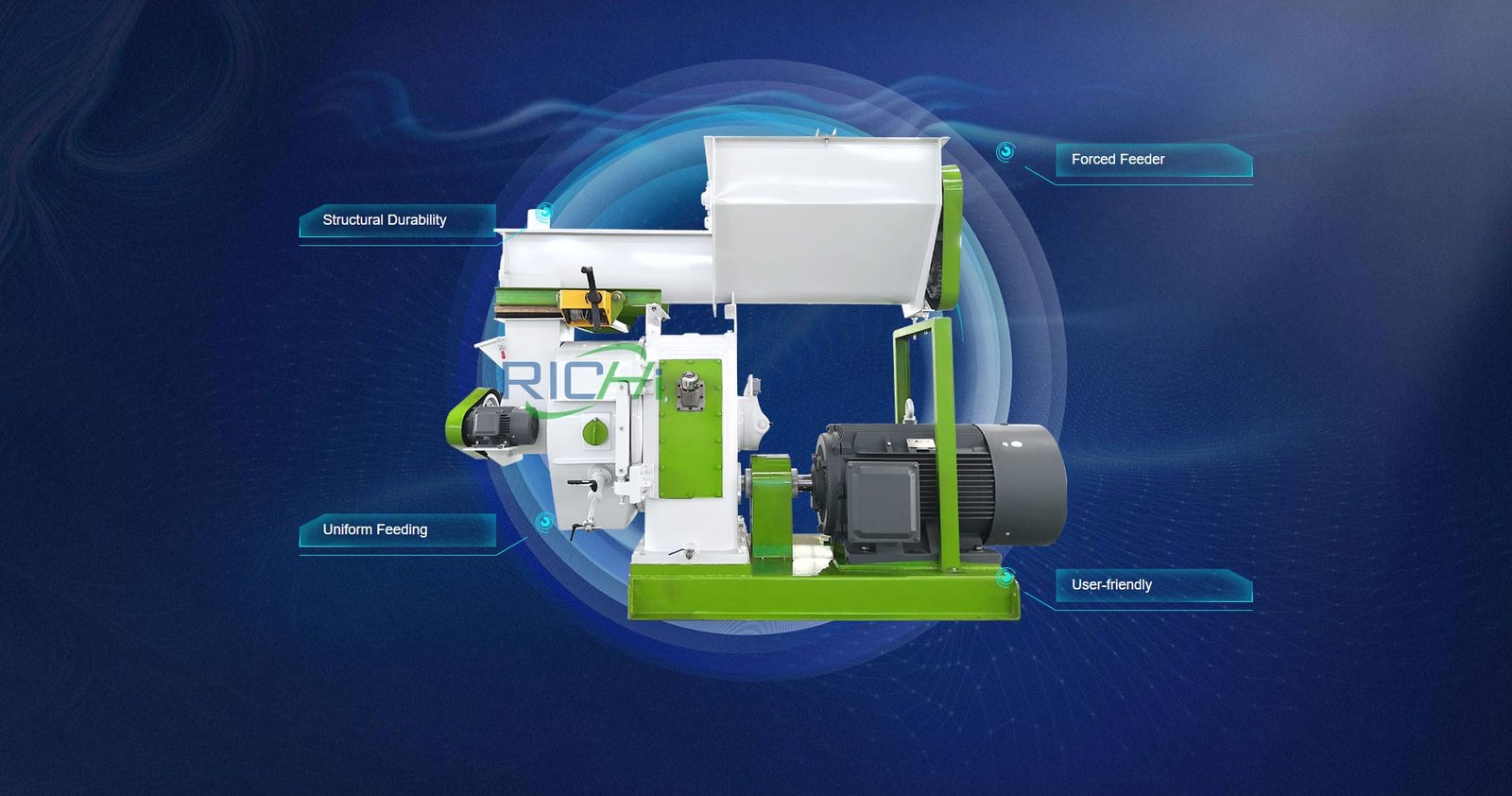

The Role of Organic Manure Making Machines

Organic manure making machines play a crucial role in transforming organic waste into a valuable resource – nutrient-rich manure. These specialized machines are designed to handle a wide range of organic materials, such as animal waste, crop residues, food waste, and composted materials, ensuring efficient and reliable manure production.The typical workflow of an organic manure making machine includes the following key stages:

- Raw Material Handling and Preparation: The first step involves the collection, sorting, and preprocessing of organic materials. This may include drying, shredding, or size reduction to ensure optimal manure production.

- Composting: The preprocessed organic materials undergo a controlled composting process, facilitated by specialized equipment and carefully monitored environmental conditions. During this stage, beneficial microorganisms break down the organic matter, releasing nutrients and stabilizing the material.

- Grinding and Sizing: The composted material is fed into a grinding mill, where it is reduced to a consistent particle size, ensuring uniform manure quality and efficient handling.

- Conditioning: The ground organic material is conditioned with water or other additives to adjust its moisture content and pH levels, optimizing the nutrient availability and microbial activity.

- Mixing and Homogenization: The conditioned material is thoroughly mixed and homogenized to ensure a consistent and uniform manure product.

- Packaging and Storage: The finished organic manure is packaged in bags or bulk containers for storage and distribution, ensuring its quality and preventing contamination.

Related post: https://www.richipelletmachine.com/bio-fertilizer-plant-project-cost/

Factors Influencing Manure Quality and Efficiency

The quality and efficiency of organic manure produced by these machines are influenced by several critical factors, including:

- Raw Material Quality: The type and quality of the organic materials used as feedstock significantly impact the manure quality and production efficiency. Consistent and uniform raw materials are essential for optimal performance.

- Composting Process: Proper composting is crucial for achieving a stable and nutrient-rich organic material, which directly affects the quality of the final manure product.

- Conditioning Parameters: The moisture content, pH levels, and any additives used during the conditioning stage play a vital role in determining the nutrient availability and microbial activity of the manure.

- Mixing and Homogenization: Thorough mixing and homogenization ensure a consistent and uniform manure product, promoting even nutrient distribution and application.

- Maintenance and Optimization: Regular maintenance and optimization of the organic manure making machine, including equipment cleaning, calibration, and process parameter tuning, are essential for maintaining optimal performance and efficiency.

Advancements and Future Outlook

The organic manure making machine industry is continuously evolving, driven by the need for increased efficiency, automation, and sustainability. Advancements in areas such as process control, energy optimization, and alternative organic materials are shaping the future of organic manure production.

One notable development is the integration of advanced technologies, such as the Internet of Things (IoT) and machine learning, into organic manure making machines. These technologies enable real-time monitoring, predictive maintenance, and optimized process control, further enhancing the performance and efficiency of the machinery.

Additionally, the industry is exploring the use of alternative organic materials, such as agricultural residues, forestry by-products, and municipal solid waste, as potential feedstocks for organic manure production. These alternative sources not only contribute to the sustainability of the industry but also provide opportunities for resource utilization and waste reduction.As the global demand for sustainable agricultural practices and waste management solutions continues to rise, the role of organic manure making machines will become increasingly crucial in meeting the needs of farmers, municipalities, and environmentally conscious consumers.

With ongoing research and innovation, these machines will continue to evolve, ensuring the efficient transformation of organic waste into valuable manure, contributing to a more sustainable and resilient agricultural ecosystem.In conclusion, organic manure pellet making machines are at the forefront of the sustainable agriculture and waste management revolution, transforming organic waste into a valuable resource.

As the world continues its journey towards a greener and more responsible future, these specialized machines will play a pivotal role in promoting circular economy principles, reducing environmental impact, and supporting sustainable farming practices, paving the way for a more prosperous and eco-friendly tomorrow.