Now all over the world, many regions have begun to vigorously promote biomass energy granules. In this environment, home wood pellet mill has its glowing and warm soil. Let’s take a look at how buyers can choose their own wood pellet mill model.

At present, there are many models of home wood pellet mills on the market, and each model has its own strengths and weaknesses. People who are new to the industry are often confused and do not know how to choose. The editor reminds buyers that when choosing a home wood pellet mill, you must choose the model that suits you. (Related post: fuel pellet plant)

1. How to choose the model of wood pellet mills for home use

At present, the mainstream models of sawdust home wood pellet mill on the market mainly include the following: flat die home wood pellet mill, horizontal ring die wood granulator, screw extrusion wood pellet mill, stamping pellet granulator, roller extrusion wood pellet mill, vertical type granulator.

First of all, let’s exclude several types of home wood pellet mills, which are extremely unreasonable for the production of biomass materials such as shavings.

The flat die wood pellet mills for home use is mostly used for small concentrate feed processing. Due to the flat die, the pressing wheel is pressed downwards, and it is easy to deform or crack after the flat die size is large. Therefore, the model is not too large and belongs to Small equipment; at the same time, due to the rotating structure of the mold, the pressing wheel is still in the granulation chamber as a whole, and the phenomenon of material blocking is easy to occur.

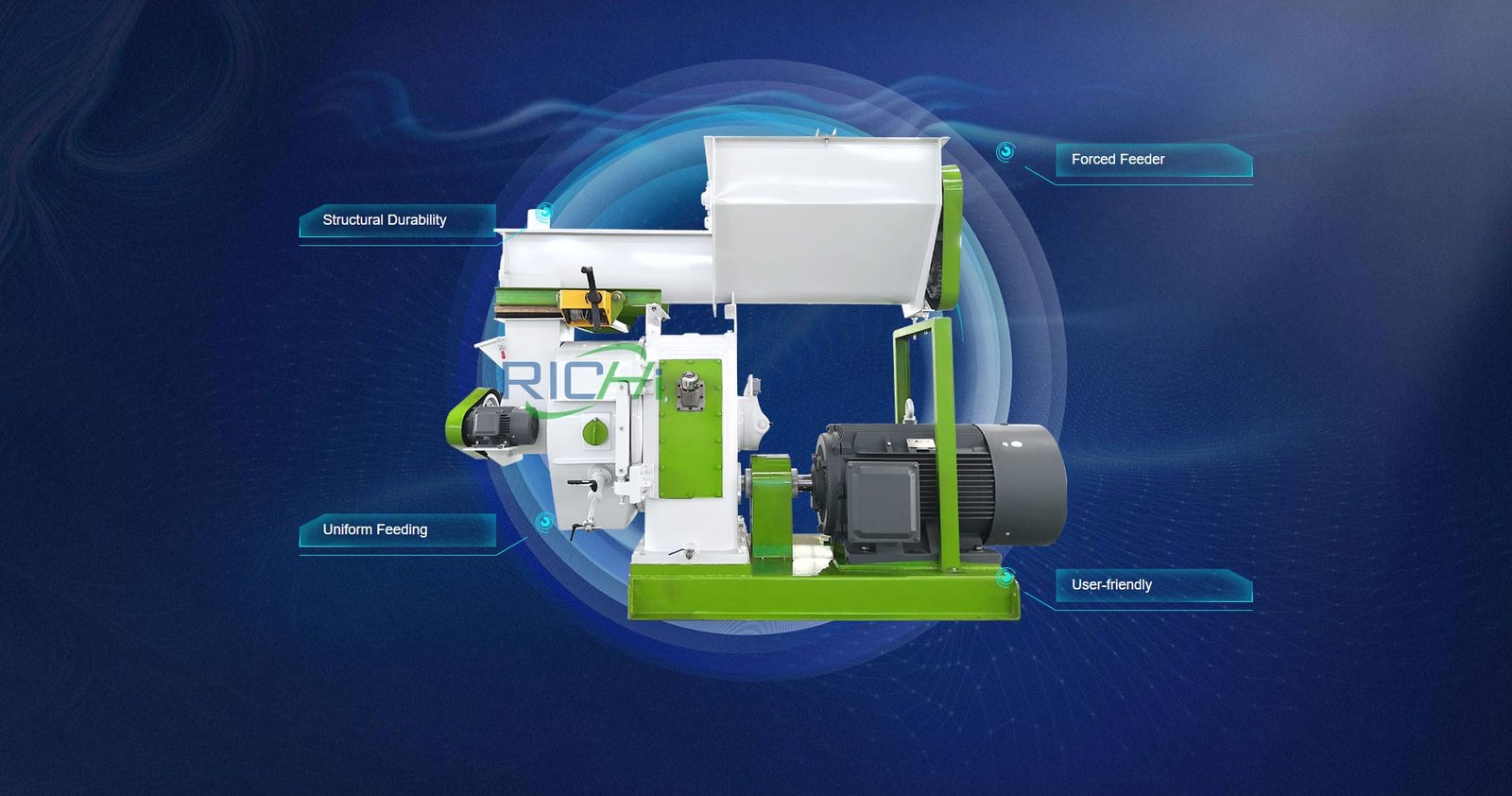

Ring die home wood pellet mill, this type of model is the most suitable model for pressing biomass materials in the current market. Its appearance can realize vertical feeding and the rotating structure of the pressing wheel will not cause fluffy and lighter biomass materials. phenomenon; the ring die can be enlarged in structure and is not limited by the process, so the large-scale equipment can be formed on the ground; the reducer adopts a special model, which can provide stronger extrusion force, and has strong resistance performance and is not easy to be damaged.

Therefore, the ring die pellet machine is the mainstream biomass pellet processing equipment on the market. (Related post: wood pellet mill for sale)

2. Application of home wood pellet mill

Every autumn and winter, the problem of straw burning in rural areas is repeated. In order to save resources and protect the environment at the same time, it is imminent to turn waste into treasure. Scientists have successively invented a variety of machines to solve this problem. The biomass pellet function can realize the resource conversion of planting energy. The advent of this home wood pellet mill can effectively solve the problem of straw burning.

The following is a good introduction to the biomass home wood pellet mill:

Biomass pellets are actually the second generation technology of biomass energy, an upgraded version of ethanol gasoline. In Europe and the United States, the development of this technology is booming. The second-generation technology uses a wider range of raw materials, including straw, cotton stalks, fallen leaves, etc., which can play the role of “turning waste into treasure”.

The benefits of biomass pellets are many: cleaning, turning waste into treasure, increasing farmers’ income, ensuring national energy security, etc. (Related post: pellet production line in Thailand)

Biomass energy can not only generate electricity, but also control oil and gas, and can also meet the needs of aircraft, automobiles, ships, etc. using liquid and gas fuels. Compared with other new energy sources such as wind energy, hydro energy, solar energy, and nuclear energy, biomass energy is the only product that can fully replace traditional fossil energy.

Many countries have abundant biological natural resources, but most of them have not been used, but caused air and water pollution. The emergence of home wood pellet mills has turned this matter around.

However, as experts have said, when these new energy products were just beginning to develop, the cost was far greater than the prices of existing products on the market due to too little output. In this case, the government should have corresponding fiscal and tax policy support to make it survive.

3. Wood Pellet Mill Machine Profit

Wood Pellet Mill Machine – How is the profit of processing biofuel pellets from waste tree branches and wood?

As a manufacturer of biological home wood pellet mills, many customers with investment intentions and new users who have just purchased will inquire some questions, that is, what is the best way to process biomass fuel pellets?

1. As a substitute for traditional mineral fuels, biomass fuel pellets are a new type of environmentally friendly biomass fuel. As an environmentally friendly fuel, the selection of raw materials is generally straw, peanut straw, wheat straw, rice husk, Rice bran, wheat bran, sawdust, sawdust, branches, bark, leaves and other solid wastes.

2. Since it is an environmentally friendly fuel, it cannot produce gases that are harmful to the environment after combustion, and no chemical raw materials such as adhesives should be added during the home wood pellet mill processing.

3. The particle density of the finished product is high, the calorific value is high, and the calorific value is large, generally about 3900 to 4800 kcal, and the calorific value after carbonization is as high as 7000 to 8000 kcal.

4. The production of biomass pellet fuel is clean and hygienic, which reduces the difficulty of feeding the staff, brings convenience to users, and saves costs at the same time.

The home wood pellet mill solves the problem of environmental pollution caused by the traditional incineration of agricultural and forestry waste, realizes the recycling of waste, and greatly helps to improve the environment. Since the establishment of the factory, developed machinery has been engaged in the research and development and production of environmental protection equipment, and its users are all over the world.

All domestic cities have been well received by the majority of users. All employees of the company will continue to work hard to provide users with more suitable high-quality and low-cost equipment as always.